-

-

TECHNOLOGY

-

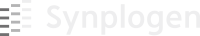

DNA Synthesis and Bioeconomy

DNA synthesis is a technique to create DNA molecules by artificially connecting the bases (A, T, G and C), which are the building blocks of DNA. While sequencing technology, which analyzes DNA sequences, is called as a technology for “reading” DNA, DNA synthesis technology is a technology for “writing” DNA.

In recent years, significant progress has been made in biotechnology, as represented by DNA synthesis and genome editing, which artificially modify the genes of living organisms. Meanwhile, digital technology has made great strides, and technologies such as robotics and Artificial Intelligence (AI) are now being applied to biological research. Against the backdrop of these advances in both biotechnology and digital technology, and the technological innovations resulting from their integration, interdisciplinary fields known as Synthetic Biology and Engineering Biology have emerged with the application of biological functions to industry in mind.

-

Further, the concept of “bioeconomy” has been proposed as an economic and social vision to be pursued beyond the further progress of the engineering use of biology. Bioeconomy is the concept of expanding a sustainable, renewable, recycling economy and society based on biotechnology. According to “The Bio Revolution” published by the McKinsey Global Institute in 2020, the bioeconomy will spill over into a wide range of industries including health and medicine, agriculture and food, consumer products, materials, chemicals and energy, and the global market for industries formed on the basis of biotechnology is expected to reach $2 to $4 trillion annually between 2030 and 2040.

-

The advent of next-generation sequencers in the mid-2000s dramatically reduced the cost of DNA sequence analysis, and the amount of bioresource data accumulated has been enormous. Following this new trend is the design and synthesis of DNA, the program that controls living organisms, and the industrial use of its functions. From “reading” DNA to “writing” DNA, the times are at that tipping point toward the realization of the bioeconomy.

Biofoundries

– Platform Companies for Driving the Realization of the Bioeconomy

In addition to basic elemental technologies such as DNA synthesis, the realization of the bioeconomy requires a platform that packages the peripheral technologies and facilities needed to master them. Companies that own such platform are known as “biofoundries”.

-

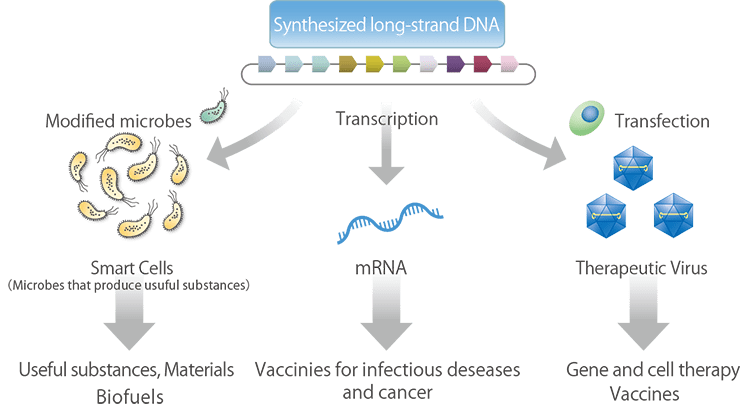

At biofoundries, highly functional cells are efficiently created by accumulating data on the DNA sequences (input information) and functions (output information) of artificially modified cells through the high-speed DBTL cycle, which consists of four processes: Design(D), Build(B), Test(T), and Learn(L). While the term “foundry” originally referred to a semiconductor chip manufacturing plant, a biofoundry handles large numbers of biosamples in automated and parallelized equipment and conducts research and development of cells (engineered cells) and production processes (scale-up) for bio-production.

-

DNA synthesis technology is an indispensable technology in the Build process of the DBTL cycle. Technological capabilities in DNA synthesis will greatly contribute to expanding the scope of design in the Design process and improving the efficiency of the entire DBTL cycle. In particular, demand for long-strand DNA is expected to increase further in biofoundries aiming to produce useful materials, as long-strand DNA is required to modify multiple genes (gene clusters), even though it is difficult to synthesize using conventional technologies. In other words, DNA synthesis is a key technology for the realization of the bioeconomy.

Utilizing our proprietary DNA synthesis technology OGAB™ and its application technology, Combinatorial-OGAB™ (Combi-OGAB™), Synplogen will work to realize the bioeconomy by providing synthetic DNA and DNA libraries to companies and research institutions in a wide range of fields, and by developing Gene Therapy Biofoundry™, a biofoundry specializing in gene therapy, as a vertically integrated business model using our own synthetic DNA as raw material.

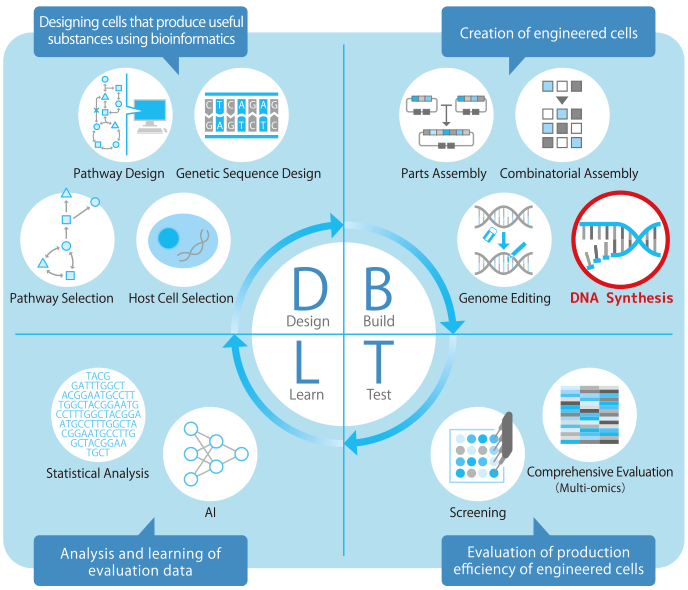

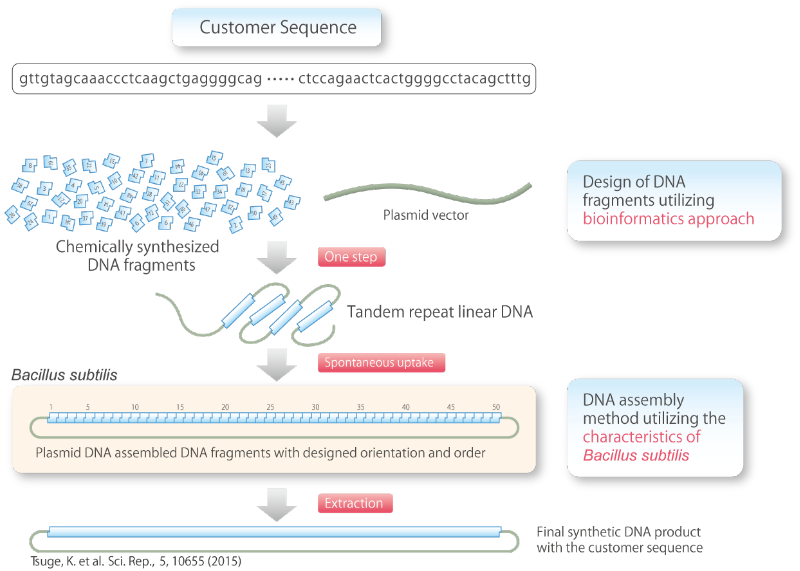

OGAB™

OGAB™ (Ordered Gene Assembly in Bacillus subtilis) is our proprietary DNA fragment assembly method that combines biotechnology and digital technology. This method is an excellent technique for synthesizing DNA of various lengths from a few kb to over 100 kb, high/low GC content, containing repeat sequences, and other complex sequences by linking more than 50 DNA fragments. We have established a production process consisting of (1) design of optimal DNA fragments for assembly (OGAB block) using our proprietary software, (2) synthesis and assembly of OGAB block using automated equipment, and (3) circularization and cloning of DNA utilizing the characteristics of B. subtilis, and succeeded in commercial production of synthetic DNA by the OGAB™ for the first time in the world.

DNA that can be synthesized by OGAB™

- DNA sequences with various lengths (from a few kb to over 100 kb)

- Complex and difficult DNA sequences

Advantages of Using Bacillus Subtilis

-

OGAB™ is the only technology in the world that uses B. subtilis for DNA synthesis. B. subtilis differs significantly from Escherichia coli in its DNA cleavage at the cell surface, the incorporation of linear DNA into the cell, and the spontaneous circularization of DNA within the cell. The greatest advantage of OGAB™ is that it avoids the in vitro plasmid DNA circularization reaction, which is a challenge with E. coli. This has made it possible to synthesize long-strand DNA, which was difficult in the past. Moreover, endotoxin-free DNA required for medical applications can also be synthesized.

-

OGAB™Synthesis Results

OGAB™ has a proven track record of synthesizing over 500 types of DNA. At Synplogen, we have successfully synthesized almost all of the DNA that we have been commissioned to synthesize.

| Sequence | Average DNA Length (kb) | Track Record |

|---|---|---|

| Glycolytic Operon | 10 | >150 types |

| Peptide Synthetase Genes | 40 | >150 types |

| Antibody-related Genes | 30 | >50 types |

| Human Genes | 100 | Several types |

| Phage Genome | 50 | Several types |

| Virus Genes | 30 | Several types |

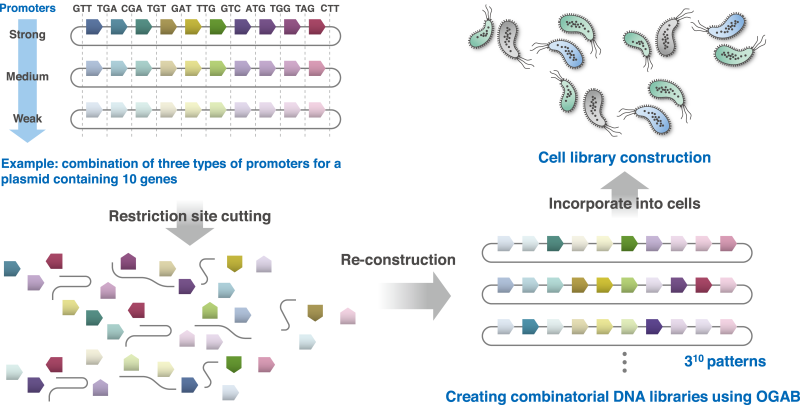

Combinatorial-OGAB™ (Combi-OGAB™)

-

The construction of engineered cells requires a large number of genes and gene clusters in which the expression factors of each gene are combined to work in a coordinated manner. However, it is extremely difficult to construct DNA libraries for countless combinations using conventional methods, and much time and effort is required to search for optimal gene clusters. To solve this problem, we use our proprietary Combinatorial-OGAB to construct large and diverse DNA libraries. This has made it possible to explore optimal gene clusters for material production in a short period of time.

-

Features of Combinatorial-OGAB™ (Combi-OGAB™)

- Suitable for a wide range of applications

DNA libraries can be constructed for various sequences such as promoters, ORFs, and terminators, and can be used for a wide range of applications, including development of viral vectors, development of multi-specific antibodies, improvement of production of useful natural products, and improvement of enzyme activity.

- Shorter breeding and development times and significantly lower development costs

Since DNA fragments used as library material can be reused, DNA library reconstructions required for each DBTL cycle can be performed in a short time and at a low cost. This shortens breeding and development time and significantly reduces development costs.

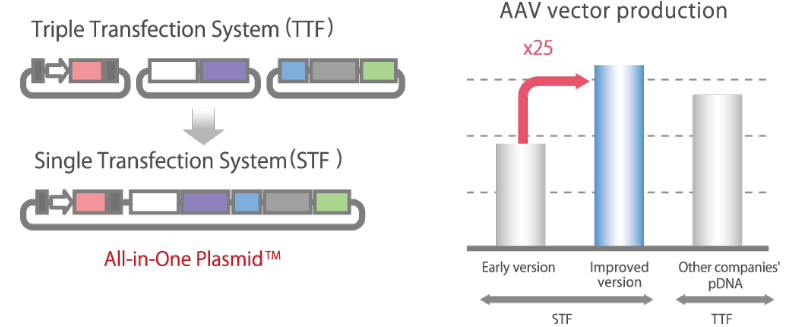

All-in-One Plasmid™

A method using three types of plasmid DNA (triple transfection) is currently the mainstream method for the production of adeno-associated virus (AAV) vectors for gene therapy, however, the All-in-One Plasmid™, developed by Synplogen, is a revolutionary technology that carries all the genes necessary for the production of AAV vectors in a single plasmid and enables the production of AAV vectors by using a single type of plasmid DNA (single transfection). Since the All-in-One Plasmid™ is synthesized from scratch using OGAB™, it can be freely designed in single nucleotide units, including the vector portion. Furthermore, by incorporating Combinatorial-OGAB™ (Combi-OGAB™), optimal gene combination patterns can be explored.

-

The All-in-One Plasmid™ technology reduces the number of plasmid DNAs required to produce AAV vectors, significantly reducing the cost of AAV vector production and the lead time required to procure plasmid DNA. At the beginning of development, there were concerns about a decrease in the production volume of AAV vectors, however, by examining the gene sequence and production method, we have succeeded in producing the same volume of AAV vectors as the conventional triple transfection method.

-

In order to utilize All-in-One Plasmid™ as a GMP raw material for AAV vectors, we have developed a culture process using a fully synthetic medium and a purification process using columns and filters that can produce high-purity All-in-One Plasmid™ in high yield. Combined with our Gene Therapy Biofoundry™ services, we will contribute to reduce the cost of AAV vector production and shorter lead time to the start of clinical trials.

CONTACT

If you have any questions about our services and technologies,

or if you would like to discuss collaboration, media coverage,

etc., please contact us using the form below.